The Potential of Plug’s PEM Electrolyzers: Decarbonizing Ammonia Production

Ammonia is a fundamentally crucial fuel source serving as the key input for nitrogen fertilizers used in food production.

Just how important is ammonia? The International Energy Agency (IEA) has concluded that about 70% of the production of it, a chemical compound combining nitrogen and hydrogen into NH3 via the Haber-Bosch process, is used as fertilizer inputs for crops such as wheat and corn globally. In the U.S., that figure is even higher at 90%.

But though a lynchpin for putting food on the table, ammonia producers also currently rely heavily upon natural gas to churn it out. And ammonia resultantly currently outputs 1.3% of all CO2 emissions, as well as 2% of global energy consumption. To understand why, here are some basics about how ammonia production works.

Ammonia production via Haber-Bosch, the process utilizing a metal catalyst under high temperatures and pressures, is fueled by natural gas. So much natural gas consumption takes place within that process that it totals 3 to 5% of the world’s natural gas production and 1-2% of the world’s energy supply at-large, according to a 2021 study published in the journal Joule.

With 70% of all ammonia currently being made from natural gas, and the rest coming from coal, production under the status quo fuels climate change. The EIA has surmised that non-green ammonia is “twice as emissions-intensive as crude steel production and four times that of cement, on a direct CO2 emissions basis.”

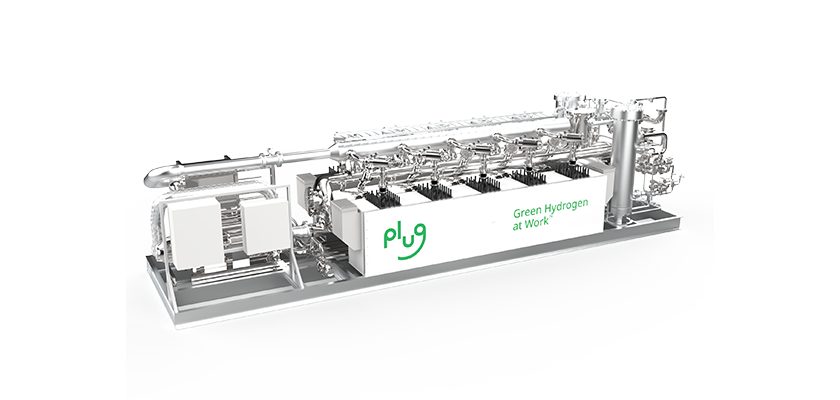

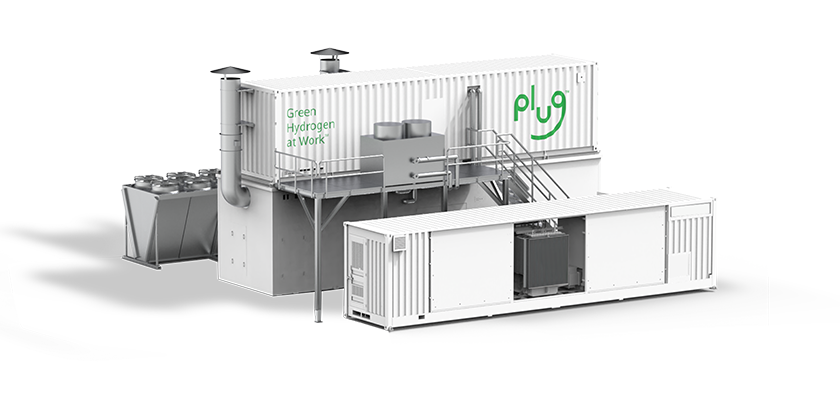

But Plug, via its Proton Exchange Membrane (PEM) electrolyzers, can mitigate the greenhouse gas emissions currently embedded in ammonia production and make the vital food-making ammonia fertilizer more sustainable. With stakeholders pushing for industrial actors to green their production processes, Plug’s technology capably aids producers in decarbonizing the chemical compound into green ammonia.

Plug’s electrolyzers use electricity to produce hydrogen from water molecules in a process called electrolysis. The only byproduct in this process is oxygen, compared to traditional steam-methane reformation (SMR), which splits out hydrogen from natural gas and yields significant greenhouse gas emissions.

Benefits of Plug’s PEM Electrolyzers for Ammonia

Contrasting with the SMR ammonia production process, Plug’s electrolyzers are not only better for the planet, but also will cut costs in the future as the forecasted commodity price of natural gas continues to rise as those of renewables fall.

The opportunity is a major one for green hydrogen and green ammonia, with 43.5% of all global hydrogen consumption currently taking place in producing ammonia. And as global prices have risen, driven by geopolitical pressures, adoption of green ammonia has also increased.

U.S. Energy Information Administration data from May 2022 show the price of ammonia in the U.S. had risen by a factor of six times in the two years prior due to the international natural gas markets price shock.

These pricing dynamics have exhibited a willingness by buyers to purchase green ammonia as an alternative.

For instance, green ammonia made via electrolysis receives a per ton offer price of more than six times that of conventional ammonia from a CF Industries-owned Louisiana facility. Yara Fertilizers, too, has recently stated global natural gas prices have prompted several plant closures. American farmers have also mulled crop-switching to lower the pricing burden.

In addition to cost-savings, hydrogen generated from Plug’s electrolyzer products is pressurized upfront to reduce downstream compression demands. This pressurization alone reduces energy consumption required for green ammonia production by 2-5% while lowering power consumption by roughly a factor of two, further reducing compression costs. This cuts costs and emissions simultaneously.

Overall, using green hydrogen in ammonia production can lower the agricultural sector’s CO2 emissions by nearly 90%, Yale Environment 360 reported in 2022. As a whole, the agriculture sector currently contributes 11% of U.S. greenhouse gas emissions and 18.4% of the global inventory.

Put succinctly, to cut costs and carbon, green ammonia produced from Plug’s electrolyzers is the way to go.

Green Ammonia Benefits, Challenges

Plug is a leading green hydrogen company, proliferating multi-applications fuel cells technology, and manufacturing electrolyzers.

Like our electrolyzers’ ability to produce green methanol — boosting the sustainability of solvent, antifreeze, and synthetic fuels production — the technology can also help the world meet its greenhouse gas reduction goals while still feeding a growing global population. Increasingly, too, green ammonia is seen as an emerging viable shipping fuel.

Green ammonia production, for all its abounding opportunities, also comes with some challenges.

The World Economic Forum has concluded that the biggest current challenge in scaling green ammonia is cost competitiveness with natural gas. As renewables like green hydrogen achieve a similar price point, the business leadership coalition has concluded that “the existing ammonia market would be opened up to a whole new set of users and thus, buyers.”

Ammonia producers are not just talking about the future benefits of electrolysis-based hydrogen. They are planning and developing projects right now. Green ammonia projects make up a significant portion of Plug’s electrolyzer sales pipeline, with projects from pilot to full-scale across multiple continents being discussed.

To learn more details about how Plug’s PEM electrolyzers can both boost and green your ammonia production needs, check out our white paper and please touch base with our electrolyzers team!

The post The Potential of Plug’s PEM Electrolyzers: Decarbonizing Ammonia Production first appeared on Plug Power.

The post The Potential of Plug’s PEM Electrolyzers: Decarbonizing Ammonia Production appeared first on Plug Power.