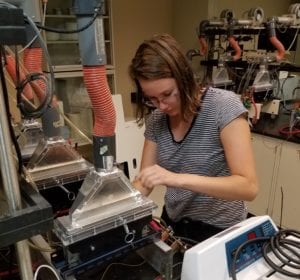

PowerSpot: Katie Cooper

This is PowerSpot, Plug Power’s monthly blog series where we highlight the Plug Power employees who inspire us and, we hope, will inspire you, too. Plug Power employs a number of interns in various parts of the business. It’s a great chance for college students to gain valuable greentech experience as they decide what direction to take in life and for Plug Power to benefit from new ideas and young energy. Today, we’re hearing from Katie Cooper, who has been interning in the material sciences area of our Spokane, WA office since December of 2018.

What is your academic background? Why were you interested in interning with Plug Power?

I just graduated from Gonzaga University with a BS in Biochemistry, but I started the internship at the end of 2018, the first semester of my senior year. We got opportunity newsletters from the department about once a week, and I was looking to expand my resume by working in a lab. I had previous experience in a microbiology lab, so Plug Power was a great opportunity to expand my knowledge and laboratory experience.

How long was your internship?

About 5 months working part-time, and another 3 working full time.

What types of things have you been doing this year?

I’ve been primarily maintaining and optimizing performance of our single cell test fixtures, which examine our materials under differing conditions. A big element of the project has been increasing the performance on those by doing things such as tweaking the setup, adjusting the fan speed, messing with compression by adding shims and increasing torque, and replacing parts as needed.

I’ve also characterized various new parts before they get tested in fuel cell stacks: new MEAs and several trials of potential replacements for the current materials we use. Occasionally I’ll help with building, conditioning, and testing of stacks that have either been returned from the field or for whatever reason don’t fit in the normal conditioning fixtures.

What does a “day in the life” of your internship look like?

I start my mornings by checking on the cells in both labs to make sure they’re still running smoothly. Then, I pull the data off the computers attached to the fixtures and process it. We track their peak performance over time, to see if they can maintain power output through hours of continuous use and varied temperatures.

Following that, I move on to whatever tests I’m running that day. I usually rebuild a few cells or take a series of measurements on any new parts, generally including thickness, weight, air permeability, and resistance. I also run a few tests (polarization curves and cyclic voltammetry) on the cells either bi-weekly or monthly to make sure there’s no degradation of any of the parts, especially the MEA, and track the trends over the life of the cell.

What have been the best things about your internship? What did you get out of it?

I’ve really enjoyed the autonomy I’ve had. Dave Lott, my supervisor, is always happy to help me with ideas on what experiments to try. But since I’ve gotten used to the normal cycle of testing and how we normally approach problems, he lets me run everything myself, and allows me to run with any ideas I have. In my previous lab experience, I was generally given a protocol and told exactly how to run everything, so designing experiments and problem-solving by myself has made me a better scientist.

Have there been any challenges you’ve had to overcome? Please elaborate.

I had very limited knowledge about fuel cells or engineering in general when I started here, so there was a huge learning curve in my first month. In spite of my chemistry background, most of my upper division work was centered around microbiology, rather than the inorganic or electrochemistry that would have been more helpful here. Therefore, the biggest challenge was just learning the details of how the cells and fixtures functioned before I could even think about increasing performance.

Would you consider a career in the fuel cell industry? Why? Why not?

Short term, absolutely. I’ve really enjoyed the challenge, and the work constantly changes, and there’s always some new and interesting issue to solve. However, long term I still love biochemistry and microbiology and will most likely transition back to pursuing those fields as my permanent career.

What advice would you give to future Plug Power interns?

I would tell them to question everything, constantly. From the way things are run, to the torque values we use, to components of the cells, there’s a reason for why everything was implemented in the first place. But with the cells constantly changing, a lot of times the testing conditions need to be changed as well. If something doesn’t make sense, it’s always a good thing to find out why we do it, and suggest possible changes. If nothing else, you learn what doesn’t work.

What is your plan for your future at this point?

Currently, I’m planning to travel for a while, and then work for another year or so before going back to school to pursue either a masters or a PhD, hopefully eventually getting to do biochemistry research full time.

We’ve enjoyed having Katie at Plug Power and wish her well with her future endeavors!

#InfiniteDrive

The post PowerSpot: Katie Cooper appeared first on Plug Power.