Hydrogen Fuel Cell Forklifts: Transforming Material Handling through Clean Energy

In logistics, warehousing, and manufacturing, hydrogen fuel cell technology is gaining momentum as companies look for cleaner and more efficient ways to operate. Among the most significant applications are hydrogen fuel cell forklifts, vehicles that run on a process producing only water and heat as byproducts. These forklifts meet the rising demand for solutions that improve efficiency while reducing environmental impact, offering an option that does not sacrifice performance.

Technology and Benefits

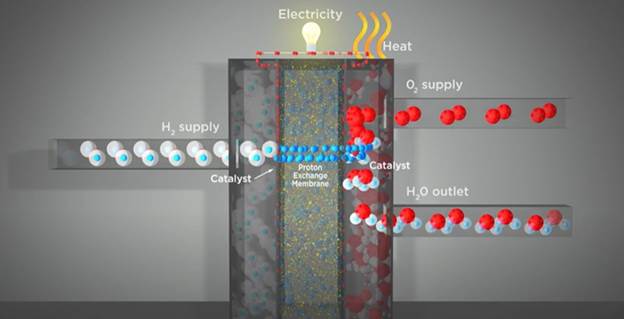

Hydrogen fuel cells generate electricity by combining hydrogen and oxygen in an electrochemical reaction. Proton Exchange Membrane (PEM) fuel cells, the type most often used in forklifts, start quickly, operate efficiently at moderate temperatures, and can be scaled to different applications. Because they produce only water and heat, they represent one of the cleanest energy technologies available.

Hydrogen forklifts can be used across a range of equipment, from small pallet jacks to heavy-duty trucks. They maintain consistent performance through a shift, avoiding the voltage drop and slower lift speeds that occur with battery-powered forklifts as energy levels decline. Refueling takes only minutes, compared to the lengthy charging times required for batteries. This advantage reduces downtime, increases labor productivity, and supports higher throughput.

Infrastructure and Planning

Hydrogen infrastructure is modular and space-efficient compared to battery charging stations, which require dedicated rooms and electrical upgrades. Refueling stations can be integrated into new or existing facilities with careful planning and site assessment. Proper placement helps minimize workflow disruption and allows room for future expansion.

Maintenance and Training

Fuel cell forklifts have fewer moving parts than combustion or battery-electric alternatives, leading to lower maintenance needs and less unplanned downtime. Successful adoption, however, depends on proper workforce training for safe fuel handling and equipment care. Partnering with suppliers for technician and operator certification ensures smooth operations and safety compliance.

Cost and Long-Term Value

When considering total cost of ownership, hydrogen fuel cell forklifts offer several advantages: faster refueling compared to battery swaps, smaller infrastructure footprints, reduced maintenance requirements, and more stable energy costs. These benefits often outweigh the higher initial investment, particularly for facilities with demanding utilization rates.

Policy and Market Drivers

Government incentives such as tax credits and grants are helping offset upfront costs, while advances in green hydrogen production are improving long-term sustainability. Building partnerships with hydrogen suppliers ensures reliable access to clean fuel and positions companies to benefit from cost reductions as the market grows.

A Pathway to Sustainable Growth

Hydrogen fuel cell forklifts represent a scalable, future-ready solution for material handling operations. For leaders in logistics, warehousing, and manufacturing, adopting this technology offers a pathway to:

- Labor productivity gains: 2–3 minute refueling versus 15–20 minutes for battery swaps

- Space optimization: 50–75 percent less floor space required compared to battery charging rooms

- Energy cost stability: Hydrogen pricing is less volatile than regional electricity rates

- Regulatory compliance: Direct alignment with emissions reduction mandates

By investing in hydrogen today, companies can increase efficiency, strengthen energy security, and accelerate the transition toward cleaner, more resilient operations.

The post Hydrogen Fuel Cell Forklifts: Transforming Material Handling through Clean Energy appeared first on Plug Power.