Fuel Cell-Powered AGVs – Hydrogen-Powered Robots Increasing Efficiency in Manufacturing

Plug Power is squarely focused on customer productivity – and providing the power to move businesses into the future with cost-effective hydrogen and fuel cell power solutions that increase productivity, lower operating costs and reduce carbon footprints.

Material handling fleets operate knowing that efficient material flow is essential to achieving high productivity levels. Plug Power’s GenDrive product suite offers facility managers a value-added solution that improves these day-to-day activities. Today, we’re discussing fuel cell-powered AGVs – another side to material handling that is currently benefiting from GenDrive. Simply put, AGVs are the industrial equivalent of driverless electric vehicles, and are used by Plug Power’s material handling customers today.

An AGV – or automated guided vehicle – is a mobile robot that travels around a facility delivering parts from one part of a campus to another, increasing plant efficiency and enabling the humans on staff to do higher level tasks. Plug Power has been powering AGVs since 2011 – and about 15% of deployed fuel cell products are used in AGVs by customers like Bridgestone, BMW and Mercedes.

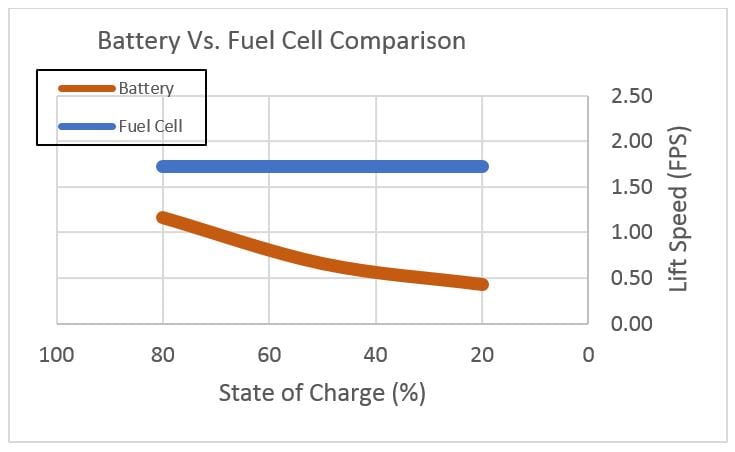

The AGV is programmed to follow a path within a warehouse operation, towing a load up to 15,000 pounds at speeds up to 4 miles per hour. AGVs have the ability to operate at maximum power 24/7 with hydrogen fuel cells power. When they get low on fuel, about every 12 hours, they are programmed to drive to a fueling station within the facility. In AGV applications, Plug Power’s fuel cell solution can increase productivity over battery-powered units because the fuel cell’s constant voltage ensures no decrease in performance.

AGVs are just another example of fuel cells as an integral solution to the road to global electrification.

The hydrogen economy isn’t just coming. It’s here.

In The Field – The Customer Experience

Facility managers value AGVs because they can run 24/7 without needing an operator. Fuel cells further increase that real economic benefit to the facility.

Real customer data tells us this:

Facilities that use AGV battery-powered fleets consistently face 20% asset downtime. This is due to the 5 to 6 hours of battery charging required for each AGV each day. Additionally, each battery-powered AGV is required to be down for another 8 hours weekly for trickle charging and cell equalization.

But with GenDrive, a refueling is needed just once every 12 hours, only takes a few minutes and not a single piece of equipment is removed from service!

A facility with 15 AGVs at $300,000 per AGV results in a $900,000 savings by using full-time fuel cell power, enabling them to “right-size” their fleet!

Your AGVs don’t quit, why should their power?

#InfiniteDrive

The post Fuel Cell-Powered AGVs – Hydrogen-Powered Robots Increasing Efficiency in Manufacturing appeared first on Plug Power.