Fuel Cell Applications 101: Where Are Fuel Cells Used Today?

Fuel cell applications are bountiful and have proven to be useful in many applications, as global energy transitions to more sustainable sources. Fuel cells, across the value chain, are increasingly seen as a vital technology to green the energy supply chain. And Plug, taking up that mantle, currently serves as an industry leader in the rollout of the technology, having innovated in the space for a quarter of a century.

Unlike an internal combustion engine, fuel cells instead intake hydrogen to generate a chemical reaction to produce power and warm water vapor. Thus, they do not rely on combustion as the propulsion mechanism. That means fuel cells don’t emit carbon dioxide, methane, or other greenhouse gasses into the atmosphere.

Fuel cells empowered by green hydrogen are seen as the gold standard use case, in which Plug is an industry leader, for climate change-mitigating energy functionality of the technology.

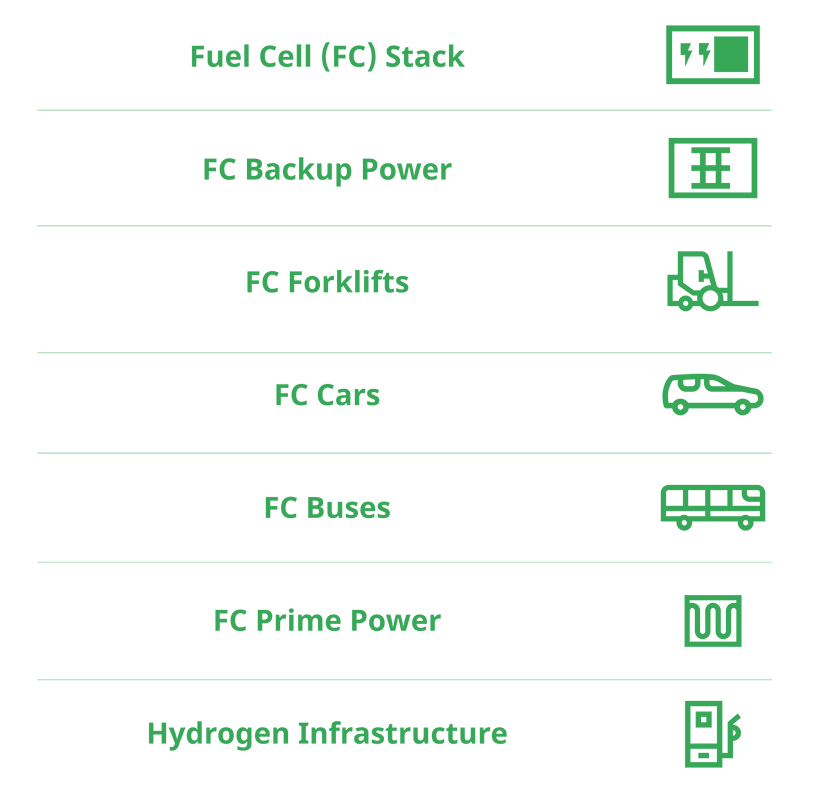

Applications for fuel cells span the value chain, stretching into areas such as material handling for distribution centers, stationary power generation of various types, and both micro- and macro-mobility. The largest active user of liquid hydrogen in the world, Plug is a robust player in nearly all these areas.

PEM Fuel Cells’ Applications, Advantages

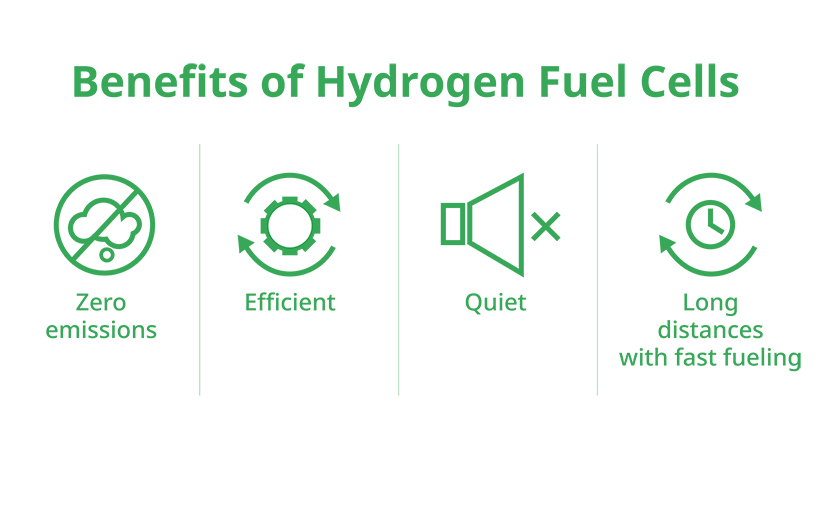

The U.S. Department of Energy notes that “Fuel cells are more energy efficient than combustion engines,” making them a key energy transition component. The University of Illinois further concludes that fuel cells generally operate at a drastically lower noise decibel level than conventional power generators, as well, further elucidating the benefits of fuel cells.

It is this versatility and ability to green energy production supply chains that serves as the central value proposition for fuel cells. A broad summary of the myriad fuel cell applications, also explained more throughout this blog post, can be seen below.

PEM fuel cells – the kind Plug develops — can empower material handling in warehouses, distribution centers, and manufacturing facilities within the sphere of e-mobility fuel cell applications.

Another emerging fuel cell application is e-mobility, empowering delivery fleets, airport fleets, long-haul trucking, port operations, and holding the potential to propel maritime operations. Separate and apart from e-mobility, stationary fuel cell applications can provide backup power in a green and more climate-friendly fashion at sites such as telecommunications hubs, railways, microgrids, data centers, all the way to feeding into the utility-scale power production grid.

The U.S. Energy Department has concluded that PEM fuel cells, at all points of their value chain, “deliver high power density and offer the advantages of low weight and volume compared with other fuel cells.”

Fuel cells of all sorts eliminate co-pollutants endemic within conventional fossil fuel production. This also provides a big win for frontline communities facing air quality impacts from incumbent combustion technology.

In aggregate, Plug has deployed 60,000 PEM fuel cell systems to its commercial customers to-date, currently gaining steam (pun intended) across the value chain.

Fuel Cells for Material Handling Equipment

The heart and soul of PEM fuel cells deployment, for Plug, comes in the form of material handling fuel cell technology via its GenDrive product suite. Material handling equipment includes items such as forklifts, narrow aisle lift trucks, pallet jacks, and stock pickers.

Plug’s GenDrive fuel cells are designed and optimized specifically to propel material handling equipment, simultaneously engineered to fit into existing electric lift truck fleets. Tersely, this means they can be dropped right into already-purchased forklift fleets, swapped directly with the previously existing incumbent battery technology.

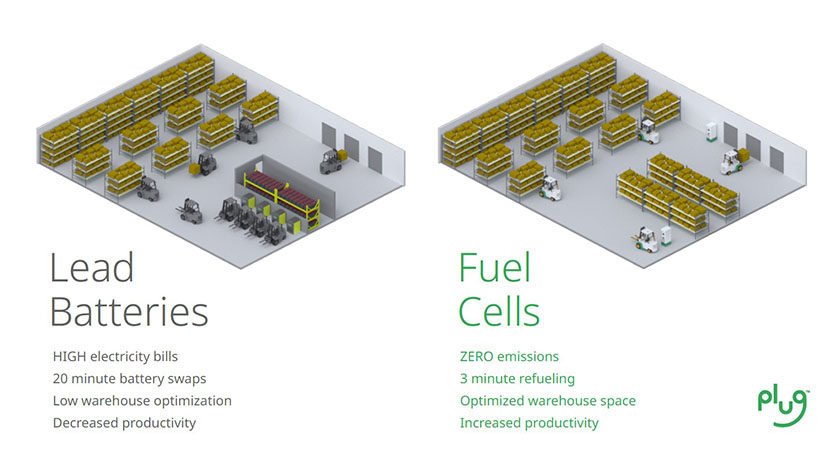

Known for their efficient use of energy, GenDrive fuel cells take less than three minutes to refuel versus the 15 minutes needed for a battery swap. While 13 minutes sounds immaterial on a one- or two-time basis business-wise, that difference causes more than 234 hours of lost productivity per forklift per year in a three-shift operation.

Further, while battery-powered forklifts see their speeds diminish by 14% during the last half of the battery charge, GenDrive fuel cells remain steady throughout a shift. This includes in freezer applications, meaning they run at full speed throughout their entire fueling payloads.

And as lead-acid batteries deplete rapidly in extremely low temperatures, Plug’s fuel cells stand strong in bitter-cold environments like freezer warehouses, functioning within temperature zones dipping as low as -22°F.

An additional metric: all of this, when tallied up, amounts to $900,000 in annual savings for the typical distribution center with 200 forklifts.

The U.S. Department of Energy has taken note of fuel cells’ ability to empower warehouses, writing that they “can efficiently provide power while at the same time producing almost no harmful air pollutants.” Plug fuel cells are a zero-emission technology.

On the contrary, the agency has pointed out the shortcomings of battery-powered material handling vehicles, writing that they require “special electrical infrastructure…[,] infrastructure for extra batteries, battery storage, charging equipment, battery changing areas, and battery maintenance (wash stations, showers, watering equipment, etc.),” while also noting the lack of efficiency compared to fuel cell forklifts.

Lastly, the agency points out that fuel cell forklifts have a better greenhouse gas emissions performance, a product life lasting double that of battery-powered forklifts, and a lower annual cost of ownership.

These beneficial uses go beyond the hypothetical. Plug’s PEM fuel cells have completed more than one billion hours of runtime, translating to more than one million driven miles throughout both North America and Europe. And these benefits have created fruitful partnerships with leading companies.

In April 2022, for example, Walmart announced an option to deploy 9,500 Plug fuel cell forklifts at 10 of its warehouses and distribution centers, all set to utilize green hydrogen. This marked the extension of a years-long partnership with the national retail powerhouse, through which Walmart already used Plug fuel cell forklifts at 22 different sites.

Shortly later in August 2022, Plug announced yet another partnership extension with another top-tier retailer: Amazon. The deal, with Plug set to provide 10,000 tons of hydrogen per year to Amazon by 2025, will increase the fleet of Plug fuel cell forklifts at 11 Amazon facilities and would yield enough hydrogen for empowering 800 long-haul trucks or 30,000 forklifts annually.

Both Walmart and Amazon, aided by Plug’s fuel cell technology, aim to go carbon neutral by 2040. As of 2022, Amazon used more than 15,000 fuel cells to power 70 of its sites. Walmart, for its part, operated 10,000 fuel cells at 41 hydrogen fuel sites across distribution centers as of January 2022.

Then in October 2022, Plug signed another deal with FreezPak Logistics, a leading third party food industry logistics company and another long-time Plug partner. The deal entails providing fuel cells, hydrogen storage and fueling infrastructure at 11 FreezPak sites across the U.S, including the three sites already in operation. Additionally, Plug intends to supply FreezPak with nearly 400 forklifts.

FreezPak told Plug at its 2022 Symposium that it has saved 31.5% in electricity costs since beginning its partnership with Plug in 2014 and gained 5,000 to 10,000 square feet per facility by no longer having to store and recharge batteries for its material handling vehicles.

“The result of the switch…has been a 100% improvement in productivity in addition to freeing up valuable floor space that had once been devoted to battery rooms,” trade publication Modern Materials Handling reported in 2020.

Globally, Plug has also formed partnerships in recent years with the Norwegian grocery wholesaler Asko, UK-based supermarket company Asda, and the South Korean logistics company Coupang Fulfillment Services to provide fuel cell-powered forklifts at the companies’ warehouses.

The opportunity to green warehouses and logistics centers with green hydrogen-powered fuel cells is massive.

Every $1 billion in online sales amounts to 1.25 million square feet of needed warehouse space, the commercial real estate firm CBRE wrote in a 2021 report. That study further notes that U.S. storage space for warehouses has increased from over 10 billion square feet in 1999 to about 17 billion square feet in 2018. Pandemic-era online shopping habits, for food and retail goods, has only driven this trend further upwards.

Further, as a 2019 literature article published in the Journal of Cleaner Production pointed out, “Warehousing activities contribute roughly 11% of the total GHG emissions generated by the logistics sector across the world.” Another 2016 paper published in the Journal of Industrial Engineering and Management concluded that warehouse-based greenhouse gas emissions “represent about 5.5% of the total [global] emissions.”

Both figures cited in these studies stand likely to rise as the industry continues to increase in scope. In short, Plug’s PEM fuel cells fueled by green hydrogen could help put a dent in those figures, playing a market disruptive role while acting as a climate solution.

PEM Fuel Cells for E-Mobility

As governments consider how to slash greenhouse gas emissions, another economic sector on their radars is the “middle mile,” or the area of transit between a port of entry into a warehouse or distribution center.

Key to greening this middle mile is e-mobility, sometimes also known as electromobility, which can happen via battery-power or hydrogen-power for light-duty vehicles. According to the U.S. Environmental Protection Agency, light-duty vehicles made up 57% of greenhouse gas emissions for the transportation sector in 2020.

As with warehouses, hydrogen engines extend range and leave more room for payload than other battery-powered solutions within the e-mobility domain. And in recent years, with that framework in mind, Plug has super-charged its entrance into the e-mobility scene, including in areas such as delivery drones, industrial robotics, delivery fleet vehicles, ground support vehicles, and at ports themselves. To do so, Plug utilizes its ProGen fuel cell product line.

At the origin point of the middle mile market, ports — heavy greenhouse gas and co-pollutant emitting entities — have begun utilizing Plug’s PEM fuel cells.

As a case in point, in June 2022, Plug signed a contract to build a $315 million plant at the Port of Antwerp-Bruges in Belgium, the second largest in the European continent. The deal includes a fuel procurement component in which Plug will provide 35 tons of green hydrogen per day as part of a 30-year contract. It also offers Plug the opportunity to sell its fuel cell-powered forklifts and other e-mobility vehicles used in the vicinity of the Belgian port.

In neighboring Germany, Plug has also made the Port of Duisburg in Germany its European service center, maintaining a focus on engineering, logistics, technical support, and maintaining an on-site electrolyzer to facilitate green hydrogen production. The site is well-positioned to expand Plug’s ports-based business line.

Further downstream, Plug also began a 50-50 joint venture in 2021 with Renault Group, creating HYVIA. The company name explains the partnership aptly: “HY” for hydrogen, “VIA” for road. The partnership aims to render carbon-free and fuel cells-based e-mobility.

Exemplifying this is the Renault Master Van H2-TECH prototype, exhibited at the 2021 Plug Power Symposium as the first fuel cell-powered van shown in North America. The vans have a range of over 300 miles, ideally situated for any industry needing a light commercial vehicle for transporting goods and packages.

Plug’s innovative uses of its PEM fuel cell technology also extends into airports, where the technology is being used within ground support equipment.

Fuel cells have also quickly emerged as a means to enable long-haul trucking. In the coming years, long-haul trucking powered by fuel cells could emerge quickly and even surpass the market share currently enjoyed by diesel-powered trucks.

Currently, heavy-haul vehicles make up 26% of the national greenhouse gas emissions portfolio in the U.S., according to U.S. Environmental Protection Agency accounting.

Seeing the promise in the technology for long-haul applications, the U.S. Department of Energy launched the Million Mile Fuel Cell Truck Consortium in 2020 to promote research and development efforts to scale the technology across the U.S. highway system.

In a study published in March 2022, the agency’s National Renewable Energy Laboratory concluded that “Due to advancements for fuel cells and clean hydrogen production, hydrogen fuel cell electric vehicles are expected to become cost-competitive for long-haul heavy-duty trucks with greater than 500-mile range by 2035.”

Fuel Cells for Stationary Power

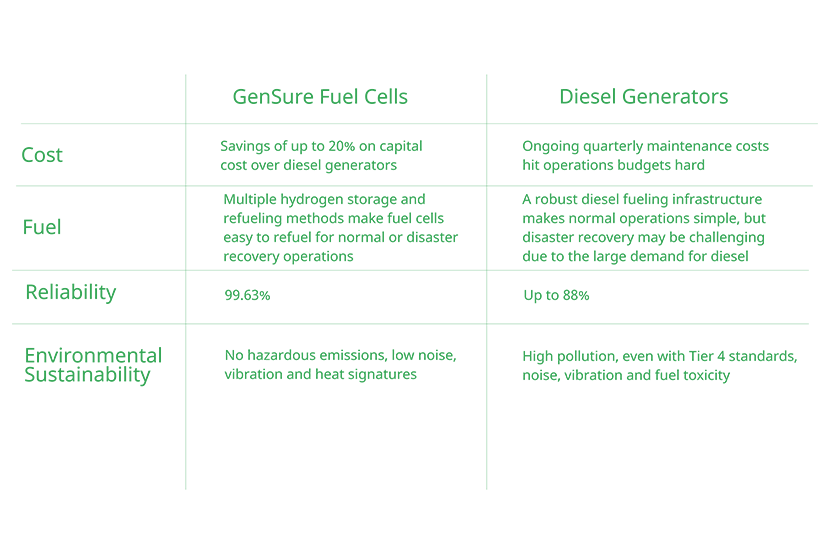

While mobility remains a heavy focus for Plug’s PEM fuel cells, stationary fuel cell applications are also on the rise. GenSure fuel cells provide the power to make that possible.

As the name implies, GenSure ensures reliable 24×7 backup generation of electricity for partners in outage scenarios and can serve to supplant diesel. In that vein, GenSure was formerly branded as ReliOn after our 2014 acquisition of a company by that namesake.

Industries Plug has assisted or can assist with GenSure fuel cells include those needing lower power, like the telecommunications industry, utilities sector partners, the railroad industry, and those needing higher power, like data centers, microgrid implementers, and others.

On the data center front, Plug formed a partnership with Microsoft to build a 3-megawatt backup power generator pilot project prototype for its data centers, enough to replace one diesel generator. It fits within Microsoft’s broader goal to eliminate dirty, greenhouse gas-intensive and community-polluting diesel backup power generation altogether by 2030.

Within the electricity utilities sector, Plug’s GenSure technology was utilized for backup generation for communications tower equipment during Hurricane Sally in September 2020, via 51 GenSure fuel cells, exemplifying the importance of the fuel cell installations as standby electricity generators. Backup power was critical to keep communication lines flowing, empowering the people who did rescue and repairs as well as the general public.

And in the telecommunications sector, Southern Linc, a subsidiary of the electricity utility company Southern Company, has deployed 500 Plug GenSure fuel cells to back up its 4G cellular network.

Plug’s fuel cells save our partner 64% in annual costs compared to traditional backup generation options. Sprint, likewise, implemented 200 hydrogen Plug fuel cells to juice their wireless network dating back to 2005 at vulnerable hurricane-prone areas such as New Orleans, Houston, as well as Jacksonville, Miami and Tampa. AT&T, for its part, has installed Plug’s fuel cells at approximately 450 locations to date.

In the railroad sector, too, CSX has plugged into Plug’s fuel cell technology in, procuring over 250 systems located at railway radio base stations and signal locations.

Aggregately, Plug has initiated more than 100 million hours backup electricity through GenSure fuel cells. Plug has also tested at 99.6% reliability when under the third party examination testing crucible. At-large, Plug has installed GenSure fuel cells at 3,000 locations in 46 states throughout the U.S and 34 countries on five continents globally.

For a more comprehensive overview of Plug’s backup power generation feats and accolades, check out this primer.

And in the microgrids area, Plug is equipped to join any prospective arrays for setups that have become increasingly important in the age of grid insecurity, be it wildfires, hurricanes, flash floods, tornadoes, and other extreme weather events. A microgrid essentially functions as a grid that can operate onto itself, disconnected and non-reliant on the broader macro-grid for electricity production.

As an example of how Plug’s fuel cells fit into such formations, the Stone Edge Farm Estate Vineyards & Winery in Sonoma, CA includes a fuel cells installation sitting as part of its broader microgrid that also features other clean energy technologies, including renewable electricity generation and battery power.

The microgrid can stand alone as an islanded source of electricity generation. At the same time, the microgrid at the Stone Edge Farm produces excess electricity sold back to local utility, Pacific Gas & Electric.

Stone Edge does not mince words on the role it sees microgrids playing going forward: “We are persuaded that microgrids are the future of energy sourcing virtually everywhere, eliminating centralized electricity generation and a landscape covered with wires.”

Plug, as the Stone Edge example makes clear, stands ready to contribute to microgrids of all shapes and sizes.

Other Fuel Cell Technologies

Other fuel cell types, beyond PEM fuel cells, include solid oxide fuel cells (SOFCs) technologies, as well as alkaline fuel cell (AFC), molten carbonate fuel cell (MCFC), phosphoric acid fuel cell (PAFC), and Direct Methanol Fuel Cell (DMFC) applications.

SOFCs, more traditional for stationary usages in generating location-centric electricity, require a temperature of 1000°C (1,830°F) to produce energy. On a global scale, solid oxide fuel cell applications include stacks for backup power generation, primarily for large businesses, data centers, and utilities.

MCFCs, which operate at a temperature of 600°-700°C (1112°F-1292°F), are similar to SOFCs in their high operational temperatures and thus, use cases. They primarily function today as a combined heat and power source within natural gas- and coal-based power plants for electricity-generating functionality.

Operating at a high but lower temperature of 60-80°C (140-176°F) compared to SOFCs and MCFCs, alkaline fuel cell applications are akin to SOFCs in that they maintain usages in “hotels, hospitals, grocery stores, and office buildings, where waste heat can also be used,” the U.S. Department of Energy notes.

AFCs are widely used for outer space voyages, in particular, and operate at a temperature of 60-80°C (140-176°F). Germanely, DMFCs also operate at a relatively low temperature, at range of 50-120°C (122 to 248°F), utilized primarily for their liquid-based rapid recharging ability in items such as cell phones, laptops, and video cameras.

Plug Propels Global Growth of Fuel Cells

Fuel cell technology is spreading globally, most robustly at the moment in the U.S. and East Asia, though 26 countries have either regulatory architecture or policy roadmaps in place to promote hydrogen fuel cell applications, according to the International Energy Agency’s “Global Hydrogen Review 2022” report.

The report points out that “By end-2021, the global [fuel cell vehicles] stock was more than 51,000, up from about 33,000 in 2020, representing the largest annual deployment of FCEVs since they became commercially available.”

In Plug’s home country, the United States, fuel cells got a huge shot in the arm through the passage of both the Infrastructure Investment and Jobs Act, as well as the Inflation Reduction Act in 2021 and 2022, respectively.

The Infrastructure Investment and Jobs Act created a $500 million grant program for “fuel cells, microturbines, or energy storage systems and components,” as well as “light-, medium-, or heavy-duty electric or fuel cell vehicles, electric or fuel cell locomotives, electric or fuel cell maritime vessels, or electric or fuel cell planes.”

Further the legislation included the launch of the Clean Hydrogen Research and Development Program to grow hydrogen “in the transportation, utility, industrial, commercial, and residential sectors” via the $1 billion U.S. Department of Energy program.

The 2022 Inflation Reduction Act, too, will expand the hydrogen market by implementing a new Clean Hydrogen Production Tax Credit, a ten-year tax credit (known as 45V) yielding up to $3.00 per kilogram of hydrogen production, similar to the already-existing Investment Tax Credit system.

The legislation also enacts a Clean Vehicle Credit program folding in fuel cell electric vehicles, concurrently lending $7,500 in federal tax credits for new hydrogen cars and up to $4,000 for used hydrogen-powered vehicles. On top of that, the law also manifests a new Commercial Clean Vehicle tax credit, ushering in up $40,000 in credits applicable to fuel cell electric trucks and buses under testing and deployment regimes.

A two-page summary of the hydrogen fuel cell incentives baked into the legislation — published by the Fuel Cell & Hydrogen Energy Association, of which Plug maintains membership — can be viewed here.

Buttressed by this dynamic policy paradigm, Plug recently unveiled its new, world-class fuel cell manufacturing facility in Slingerlands, N.Y. where more than 1,600 people will be hired.

The World Economic Forum pointed to the U.S., at-large, as ranked number two within the world’s hydrogen consuming countries.

In East Asia, as well, fuel cell applications appear ascendant.

Japan has set a target of 800,000 new hydrogen fuel cell vehicles and 1,200 new fuel cell buses by 2030. Japan’s national government has set a goal of setting up 900 fuel cell refueling stations by that time via its Strategic Road Map for Hydrogen and Fuel Cells.

South Korea, for its part and a major expansion venue for Plug as highlighted above, aims to up hydrogen fuel cell cars present in the country to 30,000 by 2030, also building 70 hydrogen fueling stations nationwide by that time. The country offers financial incentives for fuel cells via its Clean Hydrogen Portfolio Standard.

Within South Korea, Plug intends to build another PEM hydrogen fuel cells gigafactory by 2023 to continue to scale hydrogen fuel cells in a $1.6 billion joint venture with SK Group, announced in February 2021. At that gigafactory, Plug will produce and sell products spanning the hydrogen economy value chain, including but not limited to our GenSure stationary power fuel cells and ProGen fuel cell engines.

China, as the world’s top hydrogen consumer according to the World Economic Forum, also has a policy goal of deploying over one million hydrogen-powered vehicles to market by 2030.

These countries’ energy policy pushes demonstrate the importance of offering market certainty to fuel cell manufacturers and implementers via financial and tax incentives. Such incentives supply seed funding to foment fuel cells’ climb into prominence, helping businesses green their energy procurement packages.

Thanks for your interest in the myriad fuel cell applications! If this piqued your interest and you’re ready to explore Plug’s fuel cell products in more depth, please contact us.

The post Fuel Cell Applications 101: Where Are Fuel Cells Used Today? first appeared on Plug Power.

The post Fuel Cell Applications 101: Where Are Fuel Cells Used Today? appeared first on Plug Power.